Advanced Battery System Manufacturing

Global capacity, scale, and operational flexibility to serve customers across diverse end-markets

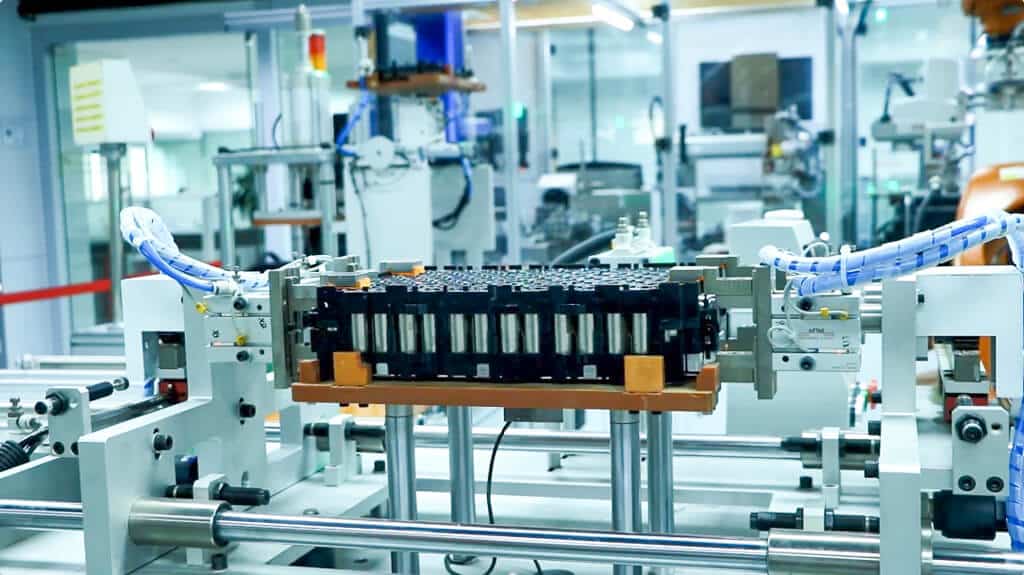

In a global economy, a battery and power systems supplier with a forward-thinking approach to manufacturing and logistics is a must. At Inventus Power, we developed expertise in designing advanced battery packs and power systems for a diverse range of industries. And we’ve leveraged this expertise to make our manufacturing processes both flexible and scalable, allowing us to meet the unique requirements of each customer’s program — whether it’s high-volume production or custom-built solutions.

Our manufacturing facilities are strategically located to align with our customers’ business initiatives. With rapid prototyping and scalable manufacturing, we’re your manufacturing partner for high-quality, safe, reliable, innovative battery and power solutions that drive success for every industry.

Whether you’re looking for a custom battery pack assembly or seeking a contract manufacturer for an existing design, discover the exceptional value of a manufacturing partnership with Inventus Power.

Inventus Power

Manufacturing at a Glance

4 Manufacturing Locations

150+ Customers Supported

2M+ Products Shipped Monthly

Our battery manufacturing operations: Strategically located for a global market

Inventus Power operates four strategically located battery manufacturing facilities – in the U.S., Mexico, China, and Brazil — each location positioned to support your specific objective and equip you to serve customers worldwide.

Woodridge, IL USA

Fulfilling US manufacturing requirements for government programs

Tijuana, Mexico

Serving North American customer base to reduce lead time and freight costs

Qingxi, Dongguan China

Supporting worldwide OEM customers and contract manufacturers

Manaus, Brazil

Servicing the Brazilian market with in-country solutions

Our unified QMS: Achieving consistent

quality across a global scale

Inventus Power prioritizes quality excellence in order to achieve customer satisfaction. Our unified Quality Management System (QMS) is the cornerstone of how our global manufacturing network seamlessly supports large scale products across multiple locations.

Our QMS ensures diligence in processes, procedures and documentation across all facilities, so all battery and power systems produced in our facilities meet and exceed regulatory standards.

We designed our QMS around compliance to diverse standards across the many industries we work with, including medical, xEV, consumer products, industrial/commercial and military/government.

We’ll tailor our QMS to meet the unique requirements of your battery or battery management system. Whether your project requires specialized testing, custom protocols or additional certifications, we’ll adapt our processes to align with your needs.

Multiple manufacturing locations allow us to split production between sites, and our unified QMS ensures consistent quality wherever manufacturing takes place, safeguarding production against market disruptions and ensuring continuity.

Our state-of-the-art battery

manufacturing capabilities

Our innovative approach to manufacturing guides your custom battery pack designs through every stage of production, from rapid prototyping to development to mass production. We handle projects ranging from single cell to 1,000+ cell battery packs, offering flexibility and scalability for all your custom battery production needs.

We have vertically integrated manufacturing capabilities, including:

Our advanced battery manufacturing technologies

We leverage our cutting-edge technology for efficiency and precision at every stage of production. Each location is fully equipped to handle full new product introduction (NPI) processes from start to finish.Innovative techniques

Our facilities feature state-of-the-art techniques engineered to optimize the overall performance and reliability of your custom battery system, including:

Automated assembly lines tailored to your needs

We offer fully automated lines for high-volume production and semi-automated for smaller, more customized projects. Depending on the scale and complexity of your custom battery, our flexible options for automation deliver cost-effective solutions while maintaining a consistent quality output.

Customized for industry standards and requirements for batteries

Compliance, reliability and performance: Our ability to manufacture batteries that meet the highest industry standards is unmatched. That’s why we’ve developed advanced manufacturing processes around the unique standards and requirements of each market we serve.

International battery safety standards

We adhere to globally recognized safety and performance standards, including UNDOT 38.3, UL 2054, and UL 62133, making us a reliable producer of battery systems that meet strict requirements for safety, transport and usage.

Medical battery industry

Compliance with IEC 60601 and ISO 13485 standards are essential because they ensure battery systems meet stringent requirements and validation protocols. Our focus on reliable performance and patient safety in all medical applications is unmatched.

xEV battery markets

We’re fully prepared to meet UL 2271 and

UL 2580, which govern battery safety and performance in electric vehicles. End users rely on these batteries for unparalleled safety and dependable operation, and we’ve designed our processes to meet them.

A cleaner battery-powered future:

Our commitment to sustainability

Your environmental, social and governance (ESG) initiatives represent a promise you’ve made to your customers — and to future generations. At Inventus Power, we help you fulfill that commitment. Our sustainability practices are designed to support your ESG goals and help promote the adoption of an electrified, battery-powered future.

Our global workforce: An overview

With our global team of employees, Inventus Power prioritizes skill enhancement, efficient practices, and a commitment to safety.

Training practices: Lean Six Sigma (LSS)

Our staff is trained in LSS principles to drive efficiency and reduce waste, and we host joint events with customers to collaborate on identifying cost-saving opportunities.

Environmental Health & Safety (EHS)

All facilities comply with local EHS regulations to ensure worker safety and environmental responsibility.

Battery Handling

& Testing

Our workforce is highly trained in the handling of lithium-ion batteries, following IPC guidelines for electronic assembly and inspection. We strictly adhere to global procedures to safely build, test, store and ship Li-ion batteries, and perform safe destructive testing to safely evaluate battery weaknesses.

See our facilities for yourself!

We encourage both customers and prospects to visit our global facilities to see our operations and cutting-edge capabilities.

Contact us to schedule a site tour!